MG Tech Services

MG Tech offers a professional service for the packaging industry that delivers timely, high-performance troubleshooting and repairs/updates resulting in plant-specific solutions.

MG Tech is recognized and acknowledged as a pivotal contact for customer service by using exceptional relationship-building skills in communicating with all levels of staff.

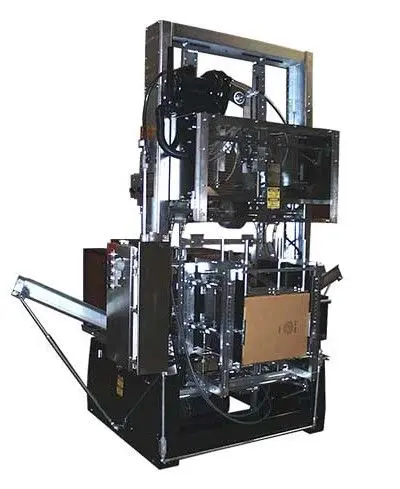

We can assist with corrugated bliss box formers, tray formers, case sealing and lidding equipment, tandem case packers, drop packers, continuous motion packers, denesters, stretch pallet wrappers, palletizers, robotics, project management, start-ups, teardowns, rebuilds, etc.

We can assist with corrugated bliss box formers, tray formers, case sealing and lidding equipment, tandem case packers, drop packers, continuous motion packers, denesters, stretch pallet wrappers, palletizers, robotics, project management, start-ups, teardowns, rebuilds, etc.

Call or contact for a quote.

Highly Skilled in problem-solving, organizational, safety-oriented, mechanical, electrical, continuous improvement, and customer service.

We have everything you need for your projects, from millwrights to electricians and technicians!

What Is a Bliss Box?

A bliss box is a three-piece shipping container consisting of a one-body matt and two end panels bonded together using hot melt, cold adhesive, or a combination of both.

These components are generally die-cut. Being made of three components allows a versatility not enjoyed by other designs. Different board grades and flutes can be used in either the body wrap or end panels to achieve superior compression strength to other box designs such as RSC.

With the added advantage of having a solid bottom, the opportunity of using different board grades and/or flutes can result in significant material savings without sacrificing box performance. As you will see below, various sealing or closure methods are also an added advantage of the bliss box.